|

Step 1: plastic mould quotation

Before a mould project start, it’s very important to know what you need, so that we can provide you with satisfying moulds and service.

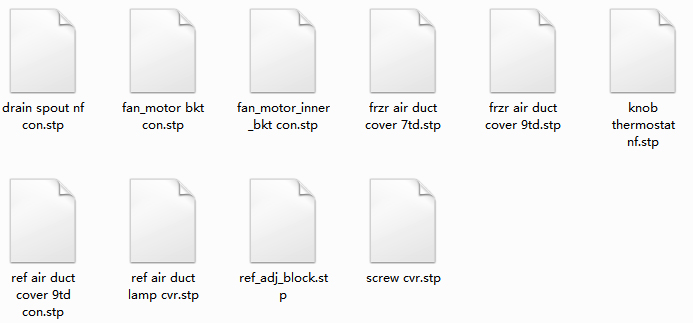

When asking for inquiries, please send us samples by express or 3D data in the format of .stp/.X_T/.prt/.igs or clear pictures with sizes and obvious features or AutoCAD drawings in the format of .dwg/.pdf or your detailed sketch with ideas.

Please also provide us following basic information: required mould steel, product plastic material, mould cavity, your plastic moulding machine tonnage, injection system, product surface requirement and size tolerance or we will give you reasonable advice according to our experience.

We will give you suggestions and reply to you with the quotation within 24hours.

|

|

|

Step 2: confirming a mould order

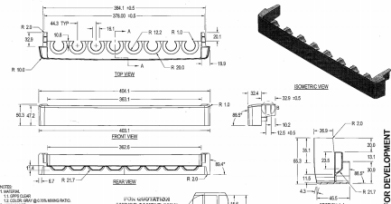

After getting satisfied mould price from us, some points need to be discussed and mutually agreed. Such as payment terms, mould requirements, mould shipment, documents needed for customs clearance, NDA (non-disclosure agreement), and other points if needed.

|

|

|

Step 3: mould designing

After receiving the pre-payment, we will start the product and mould design. Firstly, our technical department will check the sample or drawing to analyse the feasibility of production.

Secondly, the technical department will confirm the following points: product raw material, material shrinkage, product & mould size, product surface requirement, mould cavity, the function of the product, etc. before designing (if customers provide us with design, it’s faster).

|

|

|

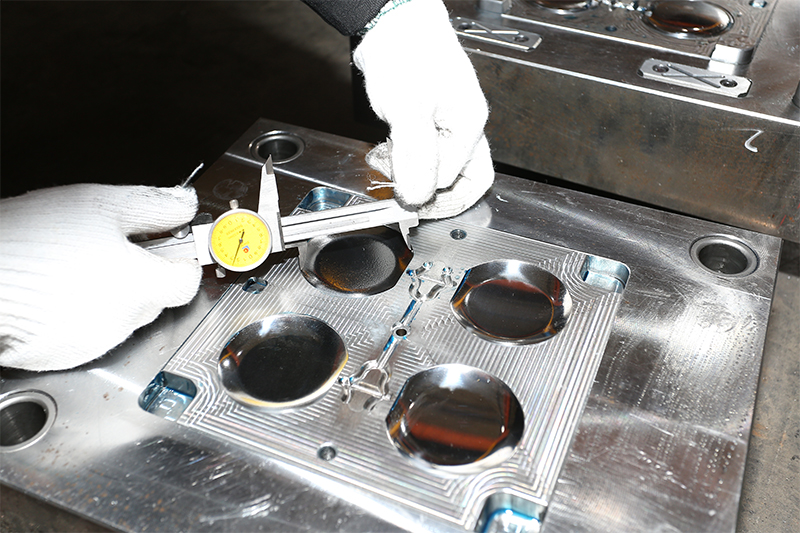

Step 4: mould machining

For every week, we will send customers the processing progress sheet with pictures or videos.

Our project manager will be in charge of all processes.

|

|

|

Step 5: mould polishing and testing

Mould polishing is an important step in mould making, especially for some need high requirement on the mould surface. Mould polishing, not only can increase the beauty of the plastic product, can improve the pieces corrosion resistance and abrasive resistance, but also be convenient to injection moulding with shortening cycle time and ejecting easily.

After all finishing, the most important step is testing. If customers can come, we are glad that they view all the testing processes by themselves. If not, we will send samples to them by express, and videos & pictures by phone.

|

|

|

Step 6: sample checking and final treatment

At the same time, we will check the mould and sample again in different aspects according to our standard and customer requirements to ensure all are ready.

|

|

|

Step 7: mould package and shipment

*Documents preparation

- After getting the information on mould delivery, the designer department will make and check the waterway drawing and oil circuit drawing. Then copying all 2D and 3D designs, video of mould test into a CD or sending to customers' email.

- Printing the file of Mould Operation Instruction, if there is mould temperature control box, also need to print Temperature Control Box Operation Instruction. All will send to our customers also.

*Mould package

- Opening the mould, and using a specific mould cleaning agent to clean all parts of mould, not allowed there is any unclean thing on mould. Then taking photos for the record.

- Spraying the anti-rust paint on the mould cavity and core surface, especially mind the parting face.

- Closing the mould and parcelling the mould with plastic vacuum film, which can prevent the mould rust also it's not easy for broken.

- Putting the spare parts and documents with mould together into a wooden box. Then nailing the wooden box for delivery.

- After all, finished, the mould will be shipped by sea or subway or aeroplane which decided by our customers.

|

|

|

Step 8: after-sale service

As for the long-term relationship with our customers, after receiving the mould and starting production, we will frequently ask if the production is smooth or if need any help. Shipping mould is not the final step of one mould order, we are more concerned about mould after-sale maintenance service so that our customers can trust us and give us the next order.

|

|