USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Quality Control System In SWY MOULD

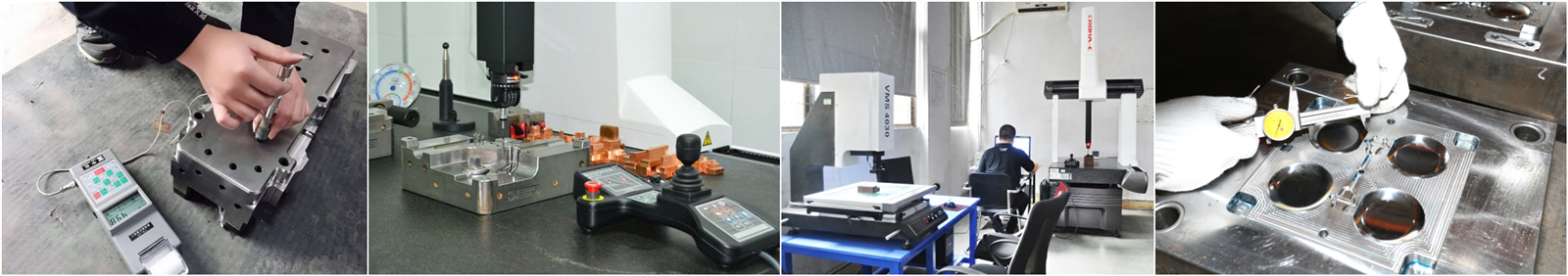

Quality creates value, we know reliable quality can help us win the deep trust from customers. SWY Quality Assurance department provides customized inspection services to meet each customer's specific requirements. With the capacity to measure both steel tool components and final plastic parts in-depth, the quality of our work is closely monitored and maintained throughout the entire manufacturing and production process. All tools and moulded parts are fully qualified by our QA staff using state-of-the-art inspection equipment. Inspection reporting is available in a variety of formats that can be customized for each unique project.

SWY MOULD attaches great importance to the QC of injection mould under various making processes:

1. Product & mould design inspection

Designs made by us or offered by customers are always analyzed in-depth by checking the moulding process feasibility, mould structure and movement feasibility of all the related plastic components etc. This helps to avoid mould modifications in the later stages and other unnecessary mould repair work which may be caused by a product design fault. We believe that if we spend more time during the product & mould designing stage we can fasten the mould making time.

2. Mould steel inspection

Plastic injection mould steels are bought from standard sellers and selected according to specific conditions and customer requirements.

Suggestions SWY MOULD provides:

*If your mould needed production quantity is high, suggested using H13 (common mould cavity/core, heat treatment HRC43-52), S136 (anti-corrosion and high mirror finish, heat treatment HRC43-52), 718S (high mirror finish, heat treatment HRC43-52), NAK80 (high mirror finish, pre-hardening HRC38-42), NAK55 (high mirror finish, heat treatment HRC43-52), 2316 (anti-corrosion and high mirror finish, heat treatment HRC43-52), 2738H (high mirror finish, pre-hardening HRC30-33), SKD61 (used for precision moulds, heat treatment HRC45-58)

*If mould needed production quantity is not so high, suggested using 2311/P20H (common mould cavity/core, pre-hardening HRC28-33), 718H (with good polishing, pre-hardening HRC33-38)

3. Mould standard spare parts inspection

All spare parts, SWY MOULD buys from the regular brand. As for spare parts, we will protect all the drawings if customers need, and offer a number of spare parts on the quotation itself. For standard spare parts, you can ask us to help you buy and send them to you and common spare parts also can purchase from your market.

4. Machining process inspection

Every week SWY MOULD will provide a weekly report with pictures or videos so that customers can know the rate of progress clearly. All sizes and machining situations will be checked by our project manager through every machining phase if there is any fault that can be corrected soon. Utilizing the top facilities to process the mould to reach high precision and high quality.

5. Mould trial inspection

Our mould trials are conducted under the supervision of experienced technical personnel who strive to adjust the moulding machine parameters and produce qualified samples. We also encourage our customers to visit the trials for their satisfaction.

Measure equipment SWY MOULD uses:

Coordinate Measurement Machines (CMM), Toolmaker's Microscope, Height Gauge, Calliper, Pin Gauge, Micrometre, etc.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. Plastic Injection Mould Manufacturers injection molding Suppliers