USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

When you want to start a child toy business or a plasti […]

When you want to start a child toy business or a plastic building blocks business, what would you need to prepare?

Here SWY Mould would like to talk with you about how to start a child toy or building blocks business with injection molds.

The starting point---finding the sample or idea

In order to start producing plastic toys, you need to have a clear idea of what do you want to create. You can search on the Internet, on the market, or let us help you find a good project of toy which you can start. SWY Mould is glad to discuss with you and help you solve the initial problem.

The main point---making good quality toy molds

During the talking with different mold-making companies, you can know about mold price, the making process, and all details of injection molding. The most important thing is to find a reliable mold-making company and begin making molds. There are high requirements on child toy final products, such as no shape corner which may damage children, so it's very important in mold making, how to arrange the part cavity, how to design the mold, and how to treat the mold surface, all need a good experienced mold-making company to help you.

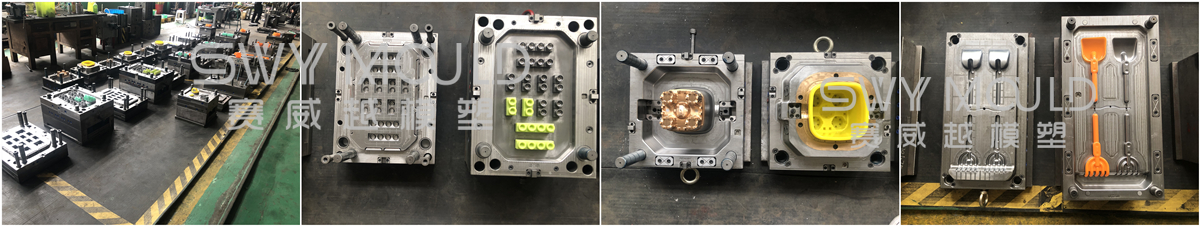

SWY Mould company has made many kinds of child toy molds, such as building block molds, toy car molds, toy bucket molds, playing sand tool molds, snowflake brick molds, and other different plastic injection molds. If you don't have the injection molding machine, also no matter, we can mass production for you. As long as you have the idea to start a plastic child toy business, others SWY all can help you.

The last point---producing and selling the toy

For producing a plastic toy, there are need three parts: plastic injection mold, plastic resin, plastic injection molding machine.

The mold is mounted in an injection molding machine. Polymers or plastics pellets are introduced into the machine to be melted. The pellets mix together with dye at high temperature and they form a thick paste. This paste, or hot molten plastic, is shot by the machine into the molds' cavities. Then it cools, it hardens, and, now a solid object, it is ejected. The plastic is still soft, though, so the toy is further hardened by plunging it in cold water.

Each one of the expelled pieces gets carefully tested for high quality. Then, depending on the type of toy, each piece will follow a different path, which means, each piece will go through a different process in the toy factory and then begin selling.

If you still have questions on what's injection molding, and how machines can produce such large kinds of plastic toys?

Kindly check our plastic child toy injection mold testing video to see how the process.

Also welcome to contact our SWY Mould company, we would like to answer you.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.