USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Several days before, one of SWY customer ordered us a s […]

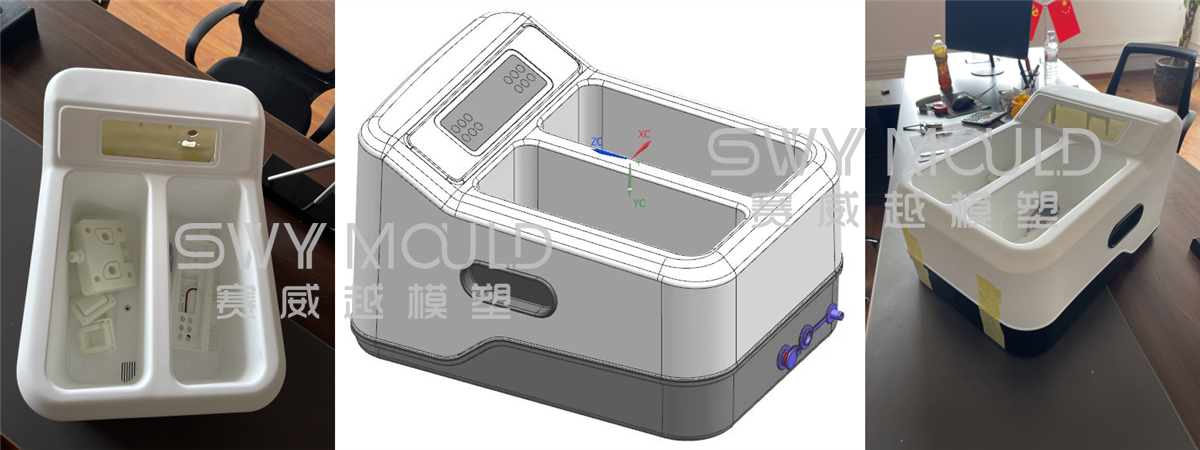

Several days before, one of SWY customer ordered us a set of plastic injection molds---plastic footbath bucket. It's a new design for our customer, so before making the molds, we need to make a 3D printing sample first and sent him for checking. After all confirmed okay, we will begin making plastic molds.

The 3D printing sample SWY MOULD made:

Do you have a 3D CAD model for your new product? Congratulations! Then what’s the next step? The first thing you probably want now is a rapid prototype or a 3D print.

The difference between 3D printing and rapid prototying

3D Printing is a technology of additive manufacturing while rapid prototyping is a group of techniques used to produce physical parts quickly from a 3D CAD model. 3D printing is one of the processing methods for rapid prototyping.

3D printing is one of the most known methods for the production of prototypes. It’s a booming industry with continuous improvements in technologies that are relatively new.

However, there are several factors to consider when you choose the right technique to create your prototype, such as cost, accuracy, functionality, material, surface roughness, etc.

Rapid prototyping technology

Rapid prototyping methods are used to produce a real scale model of part or assembly in short lead-time. When you at the early stage of a new project, a rapid prototype is going to help you progress faster.

The common rapid prototyping techniques are:

1. 3D Printing

There are several 3D printing technologies, for instance: SLA, FDM, SLS and more. FDM is the most widely used technology at the consumer level, but it has low resolution compared to SLA. If your design is complicated and you need high accuracy, then SLA is the best option.

2. CNC Machining

A subtractive manufacturing technology, which means you remove material to get the required shape by milling and lathe processes. The result is a very accurate part made from the required material! However, the cost of a CNC prototype is high because of the machine setup cost, tools, and wasted material.

3. Rapid Molding

In this technology, the prototype is produced by a low-cost mold. It’s a cost-effective process and can be beneficial for functional testing. Rapid molding offers a fast alternative to manufacture small batches of plastic parts and especially suitable for complex parts.

4. Vacuum Casting

A production method for prototypes or small production batches by using inexpensive silicone molds. These prototypes have good surface details and can be made from many kinds of casting polymers with different hardness and surface texture. The molds are usually durable for producing a quantity of 20-25 pieces.

Which kind of rapid prototyping should we work with?

If your 3D model is ready, you probably wonder which technology to use for the prototype.

There are a few factors that you need to consider:

1. Size – most 3D printers are limited in the total volume (size) of parts which is roughly 300x300x300mm, while CNC machines and other technologies can produce large parts.

2. Cost – the price of a 3D print prototype is usually the cheapest compared to other technologies. However, it depends on many parameters such as 3D printing technology, design, finish, surface quality, and quantity.

3. Materials – with 3D printers you are limited to printing materials such as ABS, PLA, etc., while with CNC machining you can use the exact material grade, for example, Aluminum 6061, Stainless steel 304, PEEK, etc. In some cases, it’s essential to produce a prototype from the same material as the product, especially when you want to make functional tests.

4. Usage – it’s essential to define what is needed from the prototype. Do you need to check the size, proportions, general look? present it to the customer? Or you need to test assembly, function, strength, and durability?

5. Complexity and Accuracy – If the design is complex and needs high precision, you’ll need to produce the prototype with CNC machining.

If you still have problems on such kind of technology, welcome to contact SWY Mould, we are glad to help you solve the confusion.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.